Equipment with laminar air flow

Self-contained trolley with laminated air flow

The stand-alone laminate trolley is designed to protect against contamination and move products and equipment between rooms with different cleanliness classes.

Advantages of the model uninterruptible power supply allows the laminate trolley to be

Stationary laminar flow unit on a frame

The laminar flow unit is designed to create and maintain an air environment with specified parameters in the workspace in order to protect the product/workpiece from environmental influences.

Advantages of the model

Module with laminar airflow

Advantages of the model

A cost-effective alternative to a centralised air purification system

creation of a zone with purified air in a finished room with a lower cleanliness class.

Mobile laminar flow module

The laminar module is designed to create and maintain an air environment with specified parameters in the working space in order to protect the product/item from environmental impact.

Advantages of the model

The

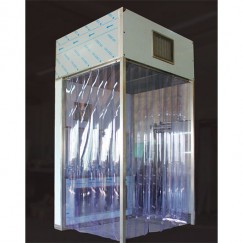

Laminar flow unit with vertical air flow (mobile)

Purpose: laminar shelter in the filling area.

Design features:

the unit is mobile (on wheels).

Laminar flow unit with a shaft

This equipment is used to create a clean area for the preparation of bulk samples, to protect raw materials from contamination, and to protect personnel from the negative effects of substances.

Laminar flow unit (suspended) with vertical airflow

Mounted above the filling line.

Design features:

Low noise and low energy consumption fans.

Water-cooled unidirectional airflow laminar flow module

Installed in the finished product sampling area.

Features:

Water cooling module installed.

Channel air cooler - VKO-90-50 (2 pcs.), complete with valves, exhaust air temperature sensor.

Con

Laminar flow unit

Installed in a finished goods warehouse.

Features:

Siemens keypad - IP54

possibility to set and adjust parameters from the keyboard

filter contamination indicator, with subsequent compensati

Laminar flow unit (suspended) with vertical airflow

Installed in the packing area of clean specialty clothing.

Design features:

Remote control capability is provided for easy activation

Laminar flow unit

The laminar flow unit is placed above the filling line.

Advantages of the model

The compactness and individuality of the laminar flow unit has made it possible to create a clean area directly above the filling li

Laminar flow unit

The laminar flow unit is placed above the filling line.

Advantages of the model

The compactness and individuality of the laminar flow unit has made it possible to create a clean area directly above the filling li

The main part of the laminar flow equipment consists of a set of filter-ventilation modules located in the upper part of the equipment, which take air from the room. Cleanliness inside the workspace area is ensured by squeezing out contaminants with a purified unidirectional (laminar) air flow. Enclosing structures are fixed around the perimeter of the equipment to direct the air flow and prevent the formation of vortices inside the work area.

Advantages of laminar flow equipment:

- A cost-effective alternative to a centralised air purification system;

- creation of a zone with purified air, both in a normal room and in a room with a lower class of cleanliness;

- compact and individual design allows them to be placed in almost any room, above the necessary equipment;

- various modification options: stationary, mobile, mounted;

- the possibility of moving the module (mobile) to any other room where it is necessary to create a classroom area with purified air;

- connection from the 220 V and 380 V network.

Additional options:

- autonomous design, which allows long-term use without connection to a stationary network;

- individual dimensions depending on the required shelter area;

- installation of rigid panels instead of conventional PVC panels;

- the module frame can be made not only of stainless steel, but also of powder-coated steel.